3 months warranty

Rental options available

Professionally Tested

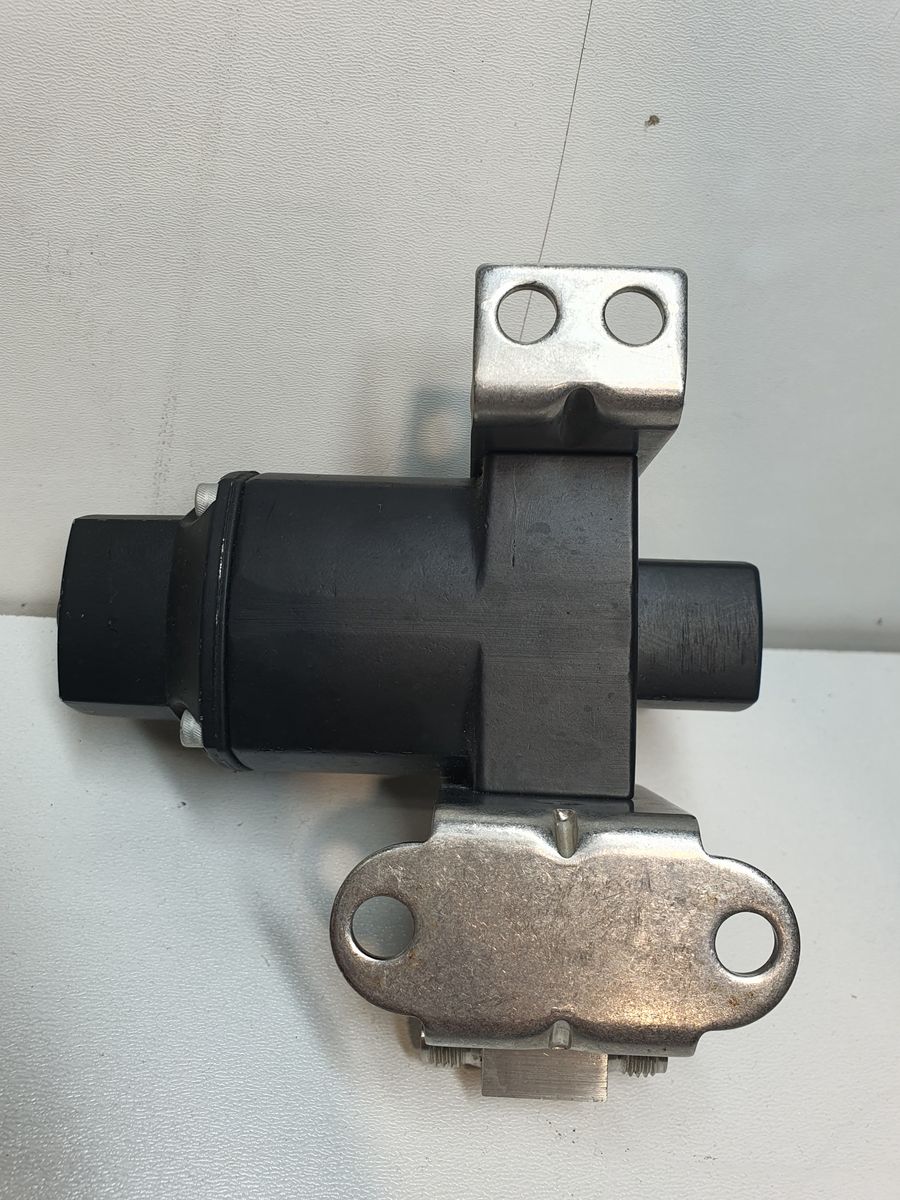

Swagelok Whitey 131 SR Actuator

Description:

The product is a pneumatic spring-return actuator designed to provide 90° rotational motion for actuating quarter-turn valves such as ball, butterfly, or plug valves. When paired with a valve body (often a Swagelok ball valve), this assembly allows automatic opening and closing of the valve using compressed air while providing a fail-safe return via the internal spring when air pressure is lost. The “131 SR” designation refers to the actuator series and spring-return configuration — meaning it is a single-acting pneumatic actuator that rotates the valve 90° and then returns to its default position on loss of air.

Key Features:

- Fail-Safe Operation: Spring-return design ensures the valve moves to a default safe position (open or closed) if supply air is lost.

- 90° Rotation: Ideal for quarter-turn valves like ball valves, delivering precise and reliable on/off control.

- Compact & Lightweight: Particularly suited for smaller valves where space and low weight are needed.

- Simple Pneumatic Control: Uses standard compressed air and can be integrated with solenoids or manual air controls for automation.

Specifications:

- Actuation type: Pneumatic, spring-return (single-acting) actuator.

- Rotation: 90° (quarter-turn) suitable for ball and similar valves.

- Actuator series: 131 Series (compact, small-displacement rack-and-pinion design).

- Actuator air displacement: approximately 1.5 in³ (24.6 cm³) — a small compact actuator size for lightweight valves/assemblies.

- Weight: 0.7kg

- Maximum recommended air supply pressure: 200 psi (13.8 bar) for the actuator. This is the maximum pneumatic pressure the actuator is designed to use for operation (not the fluid pressure in the valve body).

- Operating pressure: Standard shop compressed air or inert gas is typically used within this range.

- Temperature range (actuator): Standard designs generally operate from roughly -20 °F to +200 °F (-28 °C to +93 °C) for standard service actuators.

- Housing / Body: Anodized cast aluminum alloy with black urethane exterior finish — lightweight yet strong for industrial duty.

- Piston: Cast aluminum alloy — durable and corrosion-resistant for pneumatic actuation cycles.

- Output Shaft: Hardened 416 stainless steel — high strength to drive valve stem reliably.

O-rings:

- Standard service: Buna-N (good general-purpose elastomer)

- Fluorocarbon (FKM) and ethylene propylene as alternative seal materials depending on service options.

- Shaft Bushings: Depending on the actuator size:

- Bronze or PEEK bushings used for smooth shaft rotation.

- Spring: Zinc phosphate-plated alloy steel — corrosion-resistant spring for consistent return force.

Internal Screws & Cap Screws:

- Internal screws (for 131/133 series) are cadmium-plated steel

- All cap screws are cadmium-plated steel — strong mechanical fasteners with corrosion protection.

- Retaining Rings: Cadmium- or zinc-plated steel depending on mounting options.

- Wall Mount Bracket: Stainless steel for added durability in mounting hardware.

- Lubricant: Multipurpose hydrocarbon PTFE-based, hydrocarbon-based, or silicone-based depending on service environment (standard - lubrication covers a wide temperature range).

Swagelok Valve Body SS-42GS4-31C:

- Material: 316 Stainless Steel

- Pressure control range: 2500 PSIG

- Temperature Range: 100F - 300F

Typical Applications:

Pneumatically automated flow control in fluid and gas systems.

Industrial process systems where remote or automated valve actuation is required.

Safety shut-off or fail-safe valve control in utilities, process plants, labs, or manufacturing equipment.

Automated systems where manual valve operation is impractical.

OEM equipment requiring compact pneumatic valve actuation.

Important Notes

The 200 psi rating refers to the actuator pneumatic operating pressure, not the fluid pressure rating of the valve itself. The valve body (e.g., Swagelok ball valve) typically has a much higher fluid pressure rating. Actuator performance (such as torque and minimum required air pressure) will vary based on the specific combination of actuator size and valve torque requirements. Refer to the full Swagelok Actuation Options catalog (ISO 5211) for sizing guidance. (swagelok.com)

https://www.swagelok.com/downloads/webcatalogs/EN/MS-02-343.PDF?utm_source=chatgpt.com